SOTERIA - A 3D PRINTABLE

VENTILATOR MASK

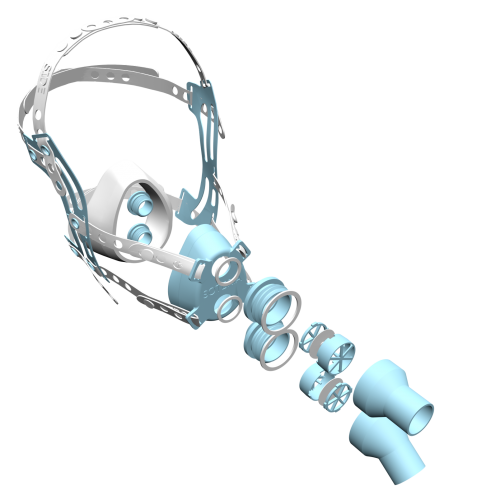

The Soteria face mask is a fully 3D printable oronasal ventilation mask compatible with common NIV-devices.

During the ongoing pandemic, hospitals around the world not only have to cope with supply shortages of masks and other personal protective equipment. In the worst affected areas, patient care can often be no longer guaranteed due to shortages of medical devices, ventilation masks or trained personal.

As 3D printing technologies have become cheaper and availability improved even in developing countries, we offer a solution to fight the shortage of ventilation masks around the world.

About the Challenge

In the face of the corona pandemic, Munich Re and Fraunhofer-Gesellschaft have launched a challenge with the aim of pooling the most capable minds with a brief to alleviate the consequences for those severely affected all around the world.

Munich Re and Fraunhofer were looking for feasible and digitally distributable construction drawings and blueprints for emergency ventilation equipment. This emergency equipment is to be used for the treatment of “non-intensive-care COVID-19 patients” in the event of a disaster. By disaster we mean the “worst case scenario”, where the capacity of the local health systems is no longer sufficient and patients therefore face immediate danger to life and limb. This equipment is meant for emergency local treatment of “non-intensive-care COVID-19-patients” to reduce demand for hospitalisation.

The selected designs will be distributed globally to governments in need and produced locally.

About the Mask

The Soteria face mask was developed to reduce the supply shortage of ventilation masks in pandemic situations. It is meant as a last resort device if conventional masks are not available or can not be obtained in time. It was inspired by the Give a Breath Challenge by Munich Re and Fraunhofer-Gesellschaft.

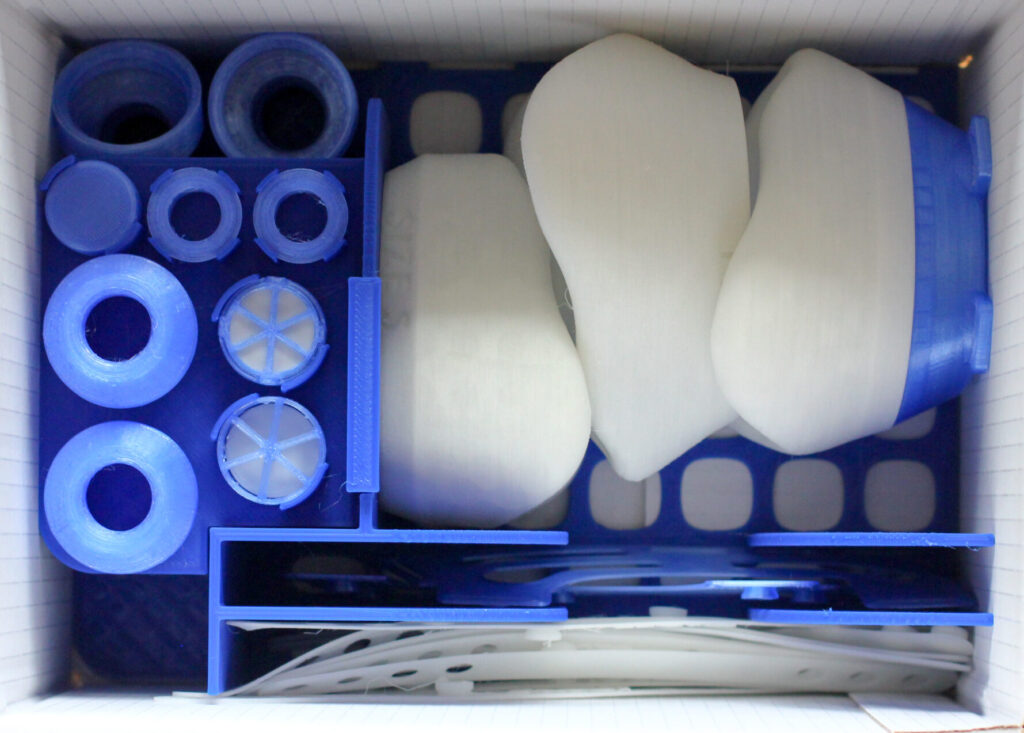

Offering a alternative to conventional methods of production, the mask can be fully 3D printed with FDM printers. This allows for decentralised production, with the printing materials being the only prerequisite.

The mask is printed with two types of materials – PLA or PETG for rigid parts and TPE for soft and flexible parts. This way we can provide a comfortable mask with a tight fit, that is still robust and can be easily assembled. With its modular design, the mask can be adapted to different situations. Various connectors that comply with international standards and 3D printed one-way-valves allow use with different ventilation systems (i.e. CPAP and BiPAP).

How it works

3 Start printing according to print settings

4 Get Back to us with feedback or questions

Technical Facts

The mask passed preliminary tests that were carried out at ETH Zürich as part of the Give a Breath – Challenge. We also tested it with equipment and support from Simulationszentrum Anästhesie Göttingen (simulation center for anaesthesia) with promising results.

Further usability and endurance tests in cooperation with Stellenbosch University SA are pending.

Click on the image to view a 3D model of the mask.

This will open a new window.

Team

Moe Lueker

M.Sc. Medical Engineering

Student (TUM)

Lukas Peschel

M.Sc. Medical Engineering

Student (TUM)

Thomas Wegele

M.Sc. Mechanical Engineering

Student (TUM)

Georg Lubins

M.Sc. Medical Engineering

Student (TUM)

Louis Krause

Medical Student (UMG)

Mira Mahavadi

M.Sc. Mechanical Engineering

M.Sc. Politics & Technology

Student (TUM)